ProCare for EFFER

Heavy duty care for your investment

Your EFFER loader crane is the critical link in your business that takes the heavy load. With Hiab ProcareTM for EFFER your reliability will never be in question. Just as your customers rely on you, you can rely on Hiab to support your business moving forward building a solid reputation and profits.

Preventative maintenance is always the best way to guarantee optimal equipment performance and avoid unnecessary costs. Take the hassle out of service scheduling and concentrate on what your business does best.The ProCareTM Essential service for EFFER always includes recommended yearly maintenance for both peace of mind and performance assurance.

How will ProCare help my business and profitability?

What’s always included?

- Secured uptime with scheduled and preventive maintenance

- Maintenance at one fixed cost

- Reduced total cost of ownership and increased resale value

- Professional technicians and original spare parts

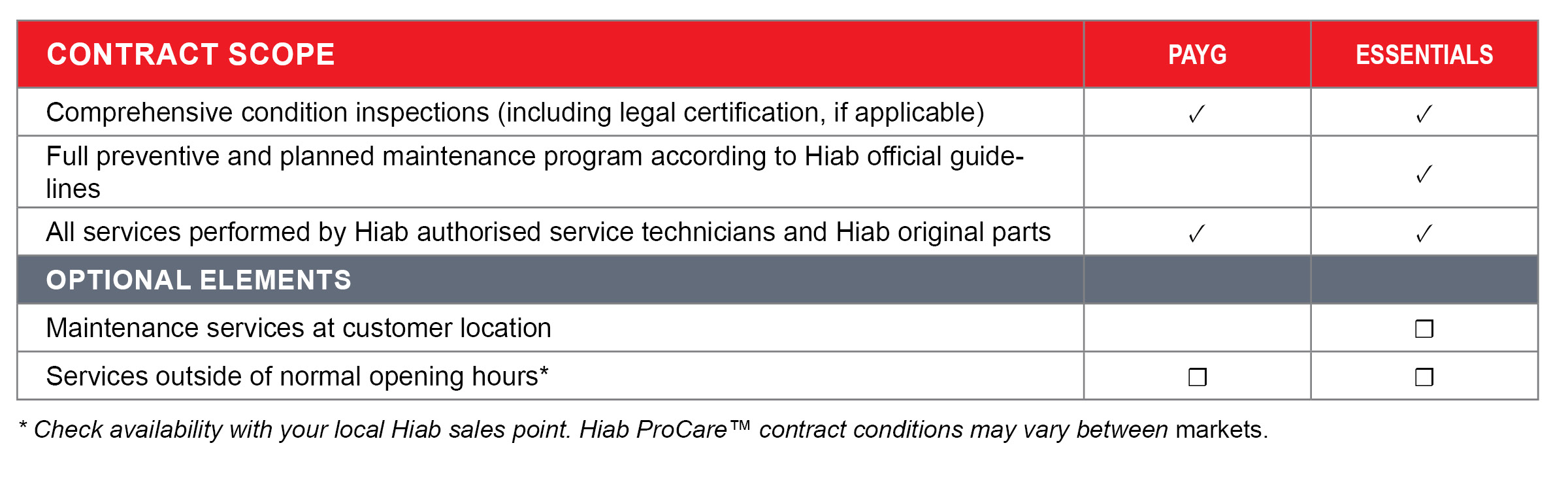

PayG

Guaranteed safety and efficiency checks with full inspection coverage. Avoid minor problems and stay focused on the big jobs.

PayG always include:

- Check of over 100 different checkpoints areas related to equipment performance, wear items and safety aspects, with overview provided on general equipment condition. Including legal certification if applicable.

- Crane operation, functions, features and crane full range of motion

- Visual inspection of safety devices, operator station, crane structure and hydraulic system

- Condition checks on items such as slide pads, hoses and pipes, electronic components

- Driver/supervisor debrief

- Recommendations on required safety or productivity related actions/repairs

Essential

An all inclusive preventative service package that will let you push your EFFER to the limits, time and time again.

Planned maintenance includes:

- Full preventative and planned maintenance programme in line with Hiab official guidelines

- Lubrication of the crane

- Operational checks and adjustments on the crane, adjustments on the control system

- Replacement of filters

- Top-up / replacement of hydraulic oil

Inspections always include:

- Check of over 100 different checkpoints areas related to equipment performance, wear items and safety aspects, with overview provided on general equipment condition. Including legal certification if applicable.

- Crane operation, functions, features and crane full range of motion

- Visual inspection of safety devices, operator station, crane structure and hydraulic system

- Condition checks on items such as slide pads, hoses and pipes, electronic components

- Driver/supervisor debrief

- Recommendations on required safety or productivity related actions/rep

Protect your investment with ProCare, find your closest dealer now

©2025 Hiab Corporation