- Forestry cranes

- Hiab Corporate

- Media

- Articles

- Ambassador Kinichi Suzuki

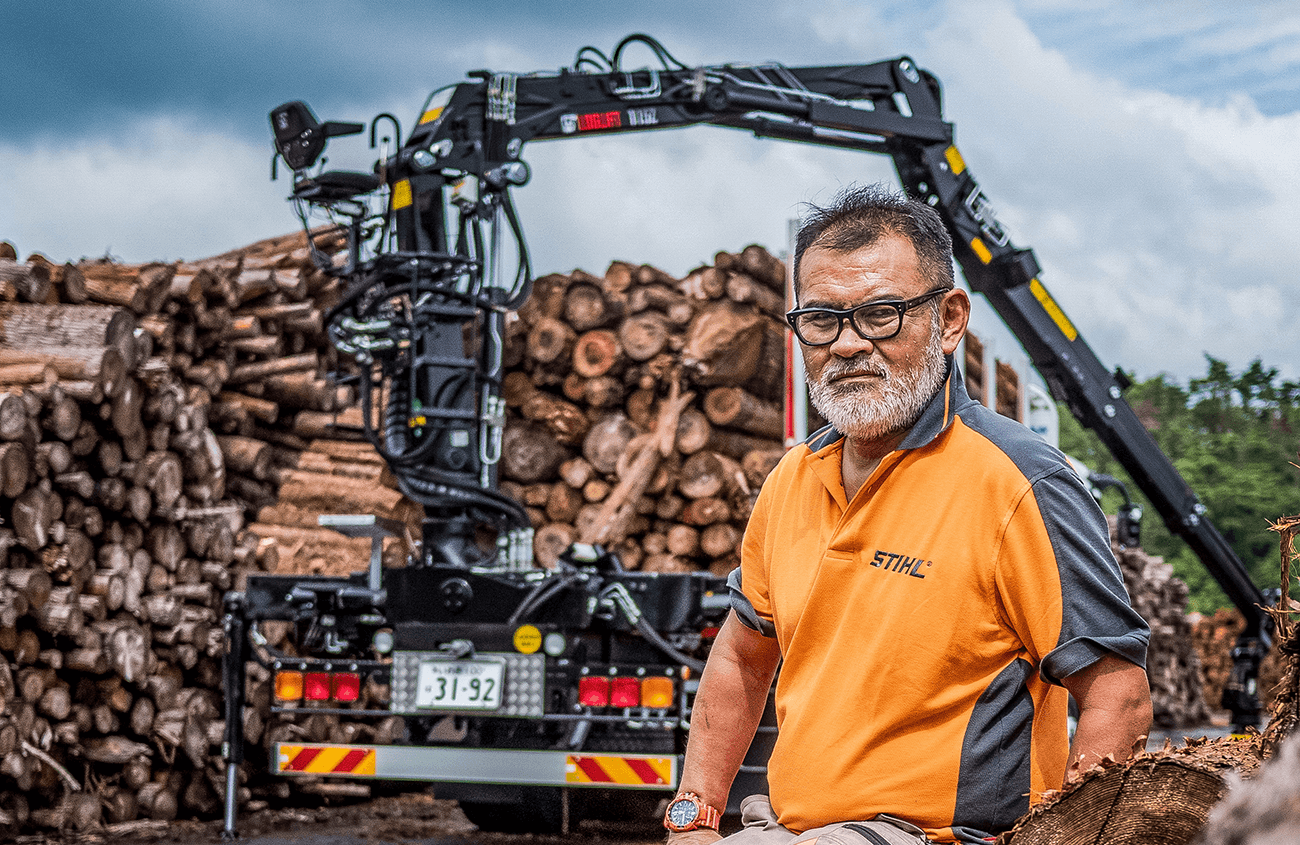

Ambassador Kinichi Suzuki

America Ya Company Fukushima, Japan

“We are proud of our safe work with no serious accidents. Also, Hiab cranes have helped us with proper operation. When I can load and unload the cargo with precision I feel happy.”

- Kinichi Suzuki

The ground is moist and large puddles are scattered all over the timber yard, placed in the Koriyama district of Fukushima prefecture. The clouds are breaking up and the temperatures are slowly rising towards +28OC. The scenery is breathtaking. The timber yard is situated in a quarry, surrounded by lush Japanese forest and on the timber yard everything is neatly organized, with piles of wood immaculately placed in straight lines and sorted according to size and quality. Between the logs, impressive black and yellow silk spiders have carefully spun their huge webs patiently waiting for the first meal of the day.

Mr. Kinichi Suzuki, president of the America Ya Company, is as usual early in place, properly and well dressed for yet another day working together with his team of 32 employees. He has just received a new truck and crane delivered personally by Mr. Satoshi Endo from Hiab’s dealer Arm Loader. Mr. Endo goes through the truck and crane together with Mr. Suzuki and one of his employees to make sure everything works as it should and is all in order.

America Ya has 16 trucks in its ownership, whereof 8 are equipped with LOGLIFT and HIAB cranes. “We use LOGLIFT and HIAB cranes for our timber-handling and transport business. Our customers are wideranging.” Mr. Suzuki says, and continues “For instance, we sell recycled waste wood to the construction companies. We also transport wood by orders from the local authorities. We buy timber from the local private companies and produce sawdust, wood chips, and so on that we sell.”

He succeeded his father taking over the American Ya company years back.“America Ya was established 57 years ago. I succeeded my father and have engaged in this business for 36 years since I was 18 years old.” Mr. Suzuki says. Taking over his fathers’ business was not as streamlined as one may think. In the beginning this was not what Mr. Suzuki wanted to do. He wanted to study and do other things but his father insisted. Eventually he changed his mind and agreed to take over the company seeing it as an exciting and important challenge and he has not regretted it since.

“Our work is very much affected by the natural environment. We encounter various kinds of situations during our operation on the different sites where we do timber handling. With the help from our machines, we can manage our work and all challenges we encounter. This job matches me very well, I like my job” says Mr. Suzuki.

The company is situated in the Koriyama district in the Fukushima prefecture. The Fukushima prefecture is populated by 1.9 million people, and as much as 68% of the total area is covered by forests. However the business climate is tough. In general, the Japanese forest industry is on the decline. Although there is a large demand for timber in Japan, the competition from wood produced abroad is extremely high. This has led to a government policy to increase the Japanese timber self-sufficiency rate. After a few years the results have started to show and the self-sufficiency rate has increased 30% from the worst dip at 18% a few years ago. Following the terrible Earthquake and Tsunami disaster and nuclear power plant accident in March 2011, the demand for alternative renewal energy resources has dramatically increased and the building of new wood bio-mas power plants give wind to the steadily increasing self-sufficiency rate. Another challenge within the forestry industry in Japan is the ever aging workforce. The forestry business work hard to attract younger workers both female and male.

For Mr. Suzuki these are challenges he meets quite consciously. It is essential to think about what values are important in order to have a sustainable business. He has some key values that are particularly important to him. He states that “Our policy is speedy action. I think it important to take timely measures to meet the customers’ needs.” He has even thought of the way he cooperates with other businesses. In addition to the 32 staff employed by the America YA company, the business is also a part of the Fukushima Prefecture Koriyama timber district cooperative. The cooperative employs an additional 30 external workers, enabling them to focus on a service that is both efficient and on time. The benefit is best formulated by Mr. Suzuki himself; “This is why I think we receive orders from our customers”.

However it is also important for Mr. Suzuki to attract good workers and to keep them as they are scarce. He puts a lot of time and effort into being a good role model, working hard together with his colleagues wearing proper safety clothes and keeping a good appearance. Safety in operation and a good work environment is important. Or as he puts it; “We have been proud of our safe work with no serious accidents. Also Hiab cranes have helped us with proper operation. When I can load and unload the cargo very tidily and neatly, I feel happy.” He even points out that “Most important is safety as well as durability.”

Mr. Suzuki puts a lot of honor into creating a good business for his customers and his employees. To him, being a reliable partner no matter what the world throws at you is the essence of a good business. He even has this expectation on his business partners.

“Hiab is the world’s leading provider. I know its outstanding performance has been built up in Europe. Similar to the other special machine makers, Hiab is a grand-scale company, and has a development capability, providing product durability. Also in a phase of competition, Hiab have survived and succeeded in the severe market. That’s why I trust in Hiab.” Mr. Suzuki concludes.

©2025 Hiab Corporation