Heavy Duty Loader and Disaster Recovery Equipment

- HIAB United States

- Application Overview

- Disaster Recovery

Hiab At Work - Disaster Recovery

Heavy Duty Loader

Reliable heavy duty loaders, HIAB loaders bring proven material handling solutions to the disaster recovery industry. Equipped with a heavy-duty grapple, the loaders can easily handle bulky waste and construction debris or downed trees, maximizing the efficiency of any recovery operation.

Heavy Duty Hooklift

Disaster recovery teams rely on MULTILIFT heavy duty hooklifts for unique and versatile emergency response solutions. MULTILIFT offers several models, including single operator, one truck capable of exchanging bodies (completely changing application) in 2 minutes or less, safe ground level access for loading and unloading equipment and the opportunity to eliminate seasonal or rarely used trucks.

Material Handler Loader Features

Operator Safety and Comfort

Hiab Loaders top seat area has been designed with operator safety in mind. The operator area is surrounded with safety rails, and the premium top seat is comfortable, ergonomic, and easy to access. The seat has wide range of adjustments, allowing it to be adjusted to the ideal working position. All standard operations are at arm's reach from the top seat, offering easy access to the stabilizer controls, truck start/stop, e-stop, and work light controls.

Estop System

Load Holding Valves

Precision Hydraulic System

Double rack'n'pinion slewing system

Service Network

We have invested heavily in our Nationwide Service and Support team as part of our commitment to our customers. With 28 branch locations and over 200 factory-trained mobile service technicians, your Hiab Loader is protected with an unrivaled coast-to-coast service network, greatly reducing the downtime of your equipment, thus reducing overhead costs.

nDurance Paint

nDurance is Hiab's state of the art anti-corrosion paint system using nano technology for the ultimate anti-corrosion coating, maintaining a rust-free reliable crane.

MULTILIFT Features

Electric Cab Controls

All MULTILIFT Optima hooklift systems are outfitted with electric cab controls as a standard feature, not an upgrade.

High Tensile Steel Construction

All MULTILIFT Optima hooklift systems are constructed using a high tensile steel, reducing the amount of steel required to get the job done without compromising the system's integrity.

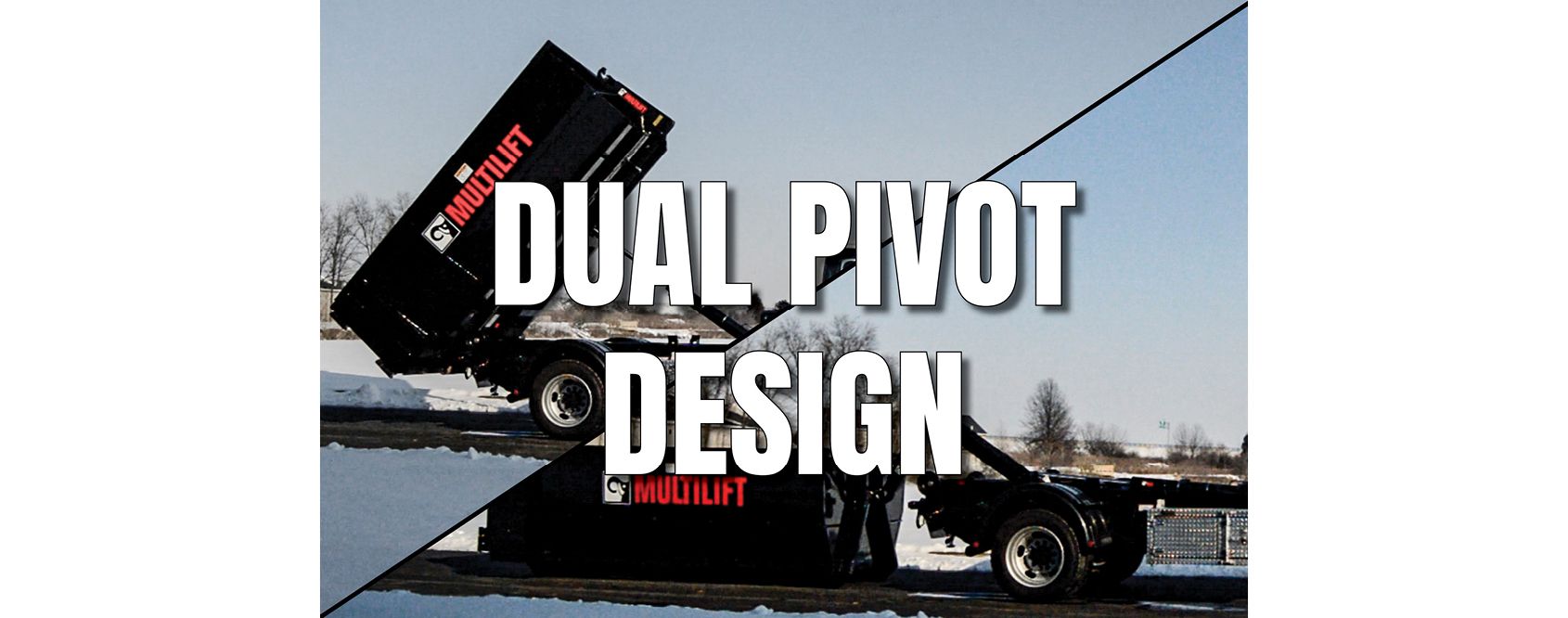

Dual Pivot Design

All MULITILIFT Optima hooklift systems incorporate a dual pivot design, for smooth loading/unloading and true dump capabilities.

Hook Safety Latch

All MULTILIFT Optima hooklifts include a hook safety latch, securing the bale bar at all times.

Body Up Warning Light

All MULTILIFT hooklift systems include a body up warning light, which is functional whenever the truck is powered on.

Sensors & Wiring

All MULTILIFT Optima Hooklifts: Outfitted with sensors and wiring that carry an IP67 rating, submersible up to 3' underwater.

nDurance Paint Process

All MULTILIFT Optima Hooklifts: Protected by the nDurance Paint Process. The steel is properly prepared prior to starting the paint process. An advanced zinc primer is applied, which virtually bonds to the steel surface. And finally, the process completed it with a finish top-coat of black. Note, all components are primed and painted prior to assembly. All non-painted components receive a zinc/nickel coating for maximum corrosion resistance.

Soft Lowering

MULTILIFT OPTIMA & ULTIMA Series: A standard feature that automatically slows the landing when completing the dump cycle.

DOWNLOAD OUR BUYING GUIDE

Whether you know exactly what you're looking for, or you are looking for more information on our product lines, download our first time buyer's guide for more information.

DOWNLOAD BUYERS’ GUIDES

Heavy Duty Loader Attachments

Download our attachment data sheets for Material Handler Loaders.

View Material Handler Attachments

Disaster Recovery Challenges

Safety

Hiab’s industry leading technology provides world class, industry leading safety features that keep operators safe and in control, minimizing risk to individuals or the environment. With the smart technology solutions of Hiab’s knuckle boom cranes, human driven errors and unsafe operations are reduced.

Efficiency

Downtime

Training

Reliability

Hiab knuckle boom cranes are the industry leaders in the area of reliability. Our premium engineering and cutting edge operation management features ensure optimum longevity and service life of your equipment. All backed up with the most comprehensive warranty in the market.

Revenue

Hiab knuckle boom cranes provide many cost benefits that are ideal for businesses with repetitive, efficient operations. With a reliable design, quality materials, game changing smart technology, and industry specific innovation, investing in Hiab equipment provides a total package for any industry.

Industry Leading Warranties

Saying you are confident in your product is one thing, warranting it is another. All Hiab equipment comes with a 2-year warranty on the entire product. Further warranty on the structural parts is extended to 3-years on Loaders and 3-years on Hooklifts (5-years on Ultima models). Meaning, Hiab covers repair or replacement of components for 2-years on all components and up to 5-years on main structural components. There's no better, or more comprehensive, warranty in our industry. Certain normal exceptions, such as replacement of consumables, apply.

Download our product Specific Warranty Statements to find out more.

View All Operator's Manuals

Click through to view all Operator's Manuals for our equipment.

Click HereMaterial Handler Loader Brochures

Material Handler Loader Data Sheets

MULTILIFT Hooklift Engineering Drawing Examples

©2025 Hiab Corporation