ProCare for HIAB

- ヒアブジャパン

- 様々なサービス

- Service and Maintenance contracts

- ProCare - HIAB

Your smart investment, protected

A HIAB loader crane is the sturdy workhouse of your team, using the latest technology to deliver safe, smart and productive results. From the first day of purchase, and every day after, your investment will pay dividends.

But, all team members need great support. With ProCareTM for HIAB, your loader crane will be kept in top shape, guaranteeing the health and safety of the operator and the surrounding environment, and helping to deliver more for your business. Secure original performance with regular preventative maintenance checks and scheduled inspects as part of the ProCareTM service contract.

ProCareはビジネスと収益性にどのように役立ちますか?

What’s always included?

- Secured uptime with scheduled and preventive maintenance

- Maintenance at one fixed cost

- Professional technicians

- Reduced total cost of ownership and increased resale value

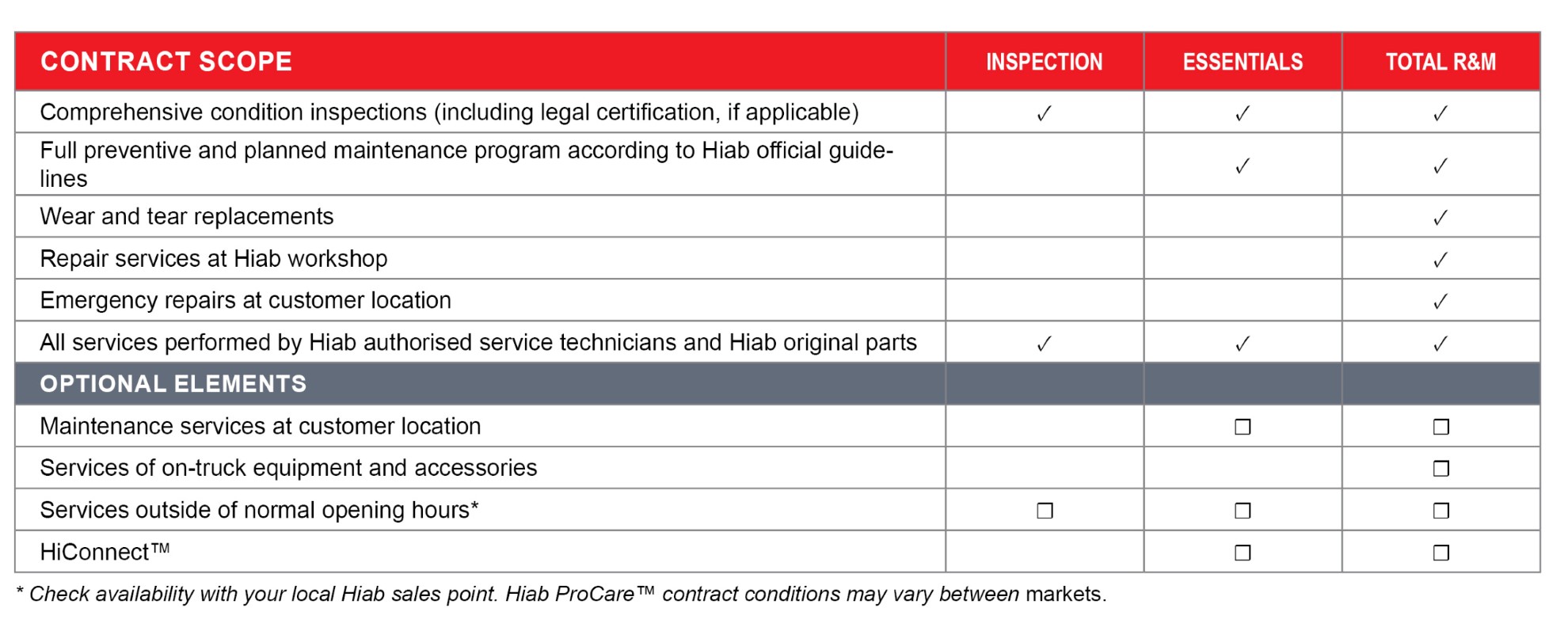

MULTILEVEL OFFERING

Create a Hiab ProCare™ service agreement that is perfectly tailored to your equipment and business needs. Guarantee the highest level of service and make the ownership of Hiab equipment seamless and integrated with your daily operations.

Our service team will create an inspection schedule including preventative maintenance and more that will let you rest easy.

Inspection

Safety and efficiency secured with robust inspections and condition checks of your equipment. Address problems quickly before they escalate.

Inspections always include:

- Check of over 100 different checkpoints areas related to equipment performance, wear items and safety aspects, with overview provided on general equipment condition. Including legal certification if applicable.

- Crane operation, functions, features and crane full range of motion

- Visual inspection of safety devices, operator station, crane structure and hydraulic system

- Condition checks on items such as slide pads, hoses and pipes, electronic components

- Driver/supervisor debrief

- Recommendations on required safety or productivity related actions/repairs

Essential

Service that keeps your HIAB loader crane in superb condition. Preventative yearly maintenance that removes the stress of unforeseen problems.

Planned maintenance includes:

- Full preventative and planned maintenance programme in line with Hiab official guidelines

- Lubrication of the crane

- Operational checks and adjustments on the crane, adjustments on the control system

- Replacement of filters

- Top-up / replacement of hydraulic oil

Inspections always include:

- Check of over 100 different checkpoints areas related to equipment performance, wear items and safety aspects, with overview provided on general equipment condition. Including legal certification if applicable.

- Crane operation, functions, features and crane full range of motion

- Visual inspection of safety devices, operator station, crane structure and hydraulic system

- Condition checks on items such as slide pads, hoses and pipes, electronic components

- Driver/supervisor debrief

- Recommendations on required safety or productivity related actions/repair

Total Repair & Maintenance (R&M)

The complete service package for total peace of mind and quality assurance. Preventative services and early detection will keep your HIAB loader crane performing at an optimum level.

In addition to the extensive list below, in case repairs are required, Total R&M covers all critical components in the crane base, boom system and extensions, hydraulic and electronic components, stabilisers, and control system.

Wear and repair include:

- Coverage of required repairs and all critical components

- Condition checks and preventive replacements of wear items such as slide pads and hydraulic hoses

- Servicing of crane accessories, hook, jib and hoist

Planned maintenance includes:

- Full preventative and planned maintenance programme in line with Hiab official guidelines

- Lubrication of the crane

- Operational checks and adjustments on the crane, adjustments on the control system

- Replacement of filters

- Top-up / replacement of hydraulic oil

Inspections always include:

- Check of over 100 different checkpoints areas related to equipment performance, wear items and safety aspects, with overview provided on general equipment condition. Including legal certification if applicable.

- Crane operation, functions, features and crane full range of motion

- Visual inspection of safety devices, operator station, crane structure and hydraulic system

- Condition checks on wearing items

- Driver/supervisor debrief

- Recommendations on required safety or productivity related actions/repairs

ProCareで投資を保護しましょう。今すぐ最寄りのディーラーを検索。

©2025 Hiab Corporation