Instalacje standardowe

- Hiab Polska

- Instalacje

- Instalacje standardowe

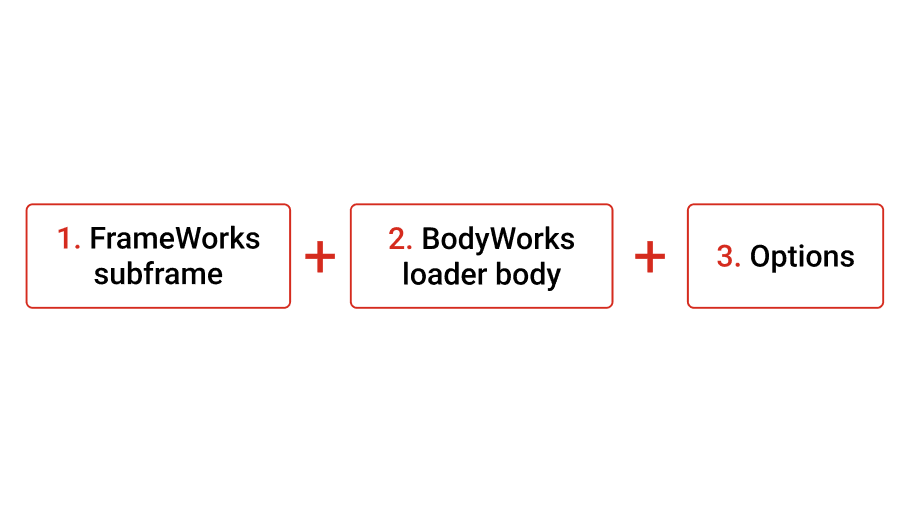

Choose your installation

First choose a FrameWorks subframe then a BodyWorks loader body for your FrameWorks subframe and lastly additional mounting accessories and front stabilizers.

1. FrameWorks subframes for heavy range cranes

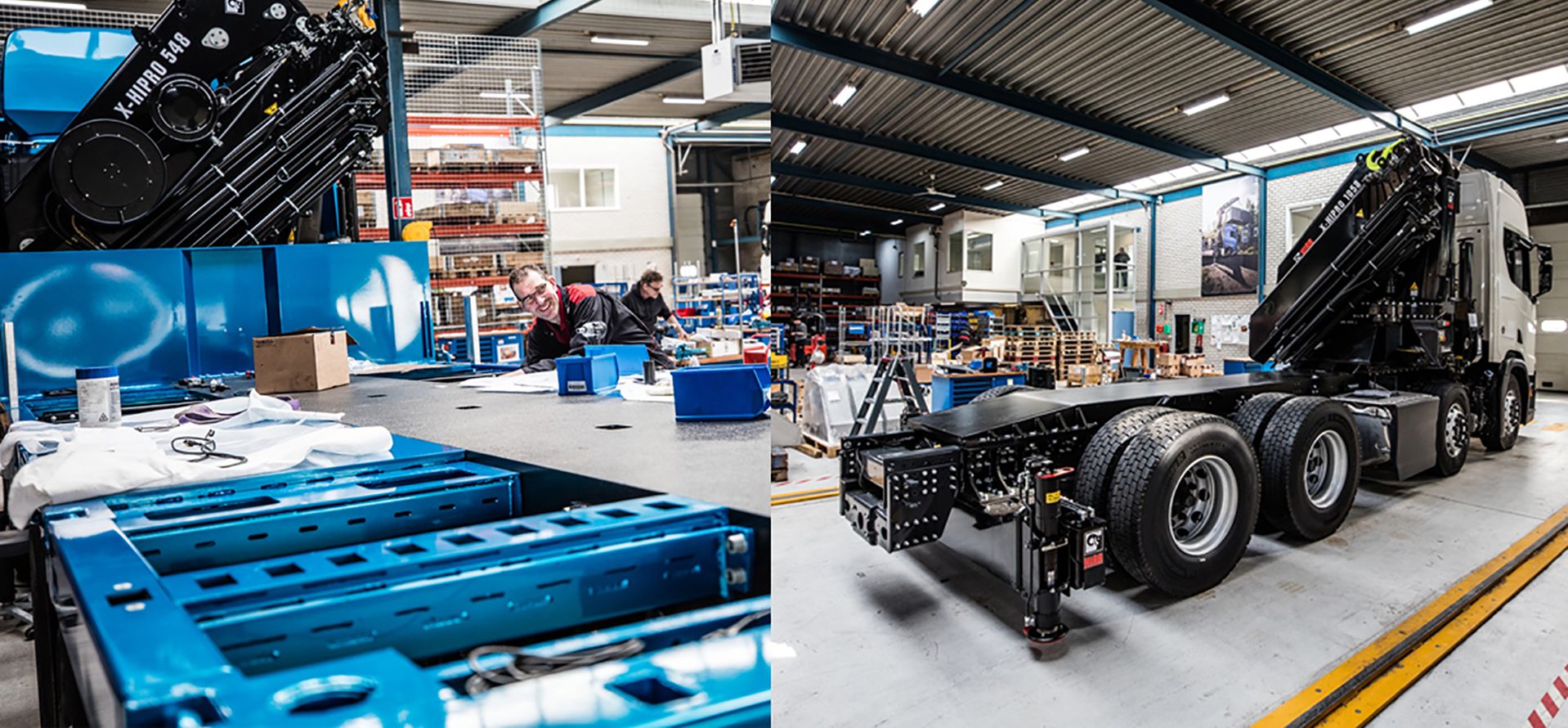

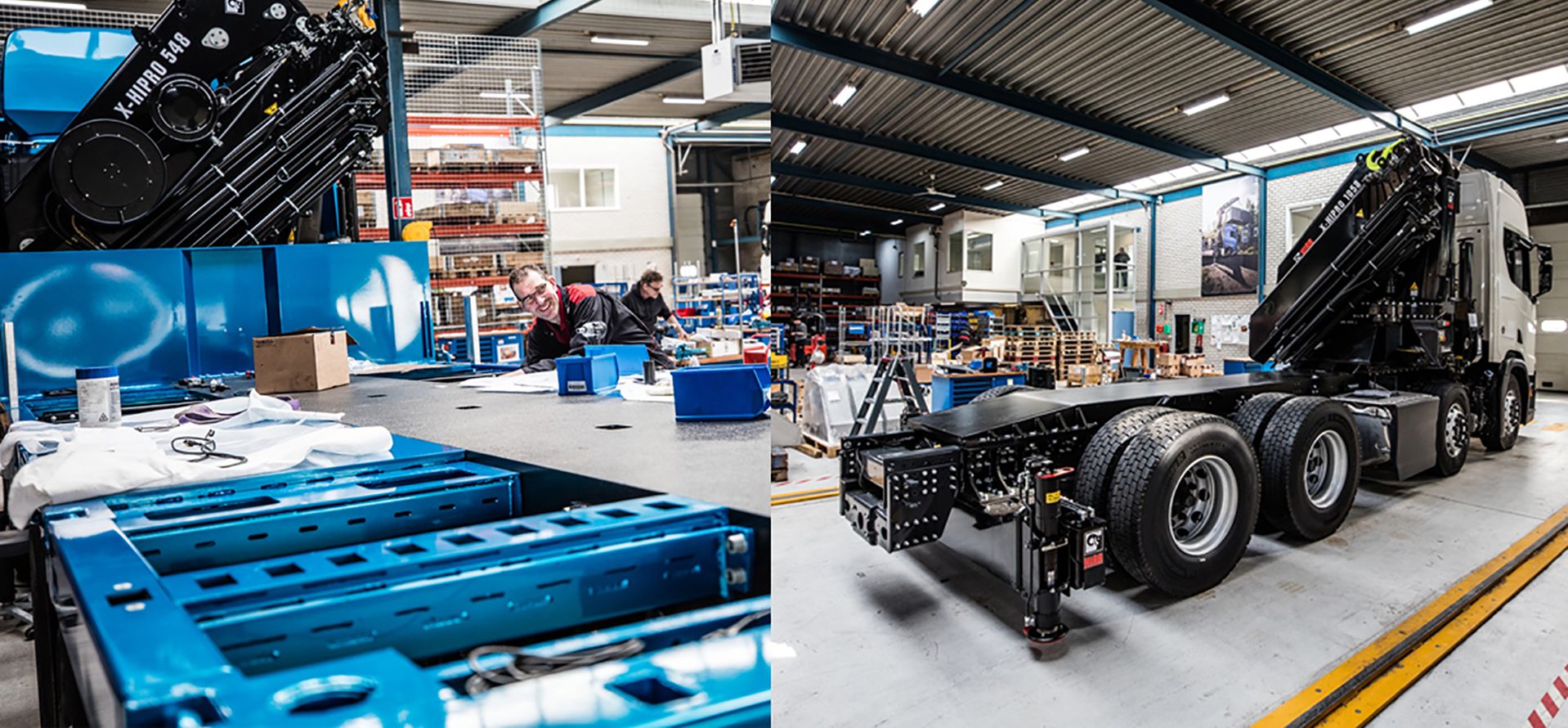

Hiab FrameWorks is the pre-manufactured, fully bolted system with subframe solution to install the heavy range HIAB loader cranes. The patented installation package offers a standardised solution heavy crane subframes and it is complete with pump, tanks and auxiliary stabilizers.

2. BodyWorks loader bodies for heavy range cranes

Hiab BodyWorks is a modular bolt-on system to create a flatbed and drop-side bodies out of your FrameWorks subframe. The unique concept provides customised options for loader bodies through innovative and cost-efficient solutions. A combination of well thought-out standard configurations plus easily interchangeable modules, options and accessories gives you total flexibility.

3. Mounting accessories and front stabilizers

Our options include:

- Different oil tank solutions

- HIAB auxiliary stabilisers

- Variable pump

- Tank supports and other bracketry

1. FrameWorks subframes

Benefits

Tougher without a doubt

Hiab FrameWorks means a rugged subframe with extreme torsion rigidity – for up to 40% greater stability.

The Hiab FrameWorks system is a CE-certified package that takes full advantage of Hiab manufacturing capabilities. Designed for fully automated production, including robot welding and advanced cataphoretic dip painting, create a lasting subframe with incredible torsion rigidity. The latter limits stress on the truck chassis and works with VSL or VSL PLUS to provide capacity-enhancing stability.

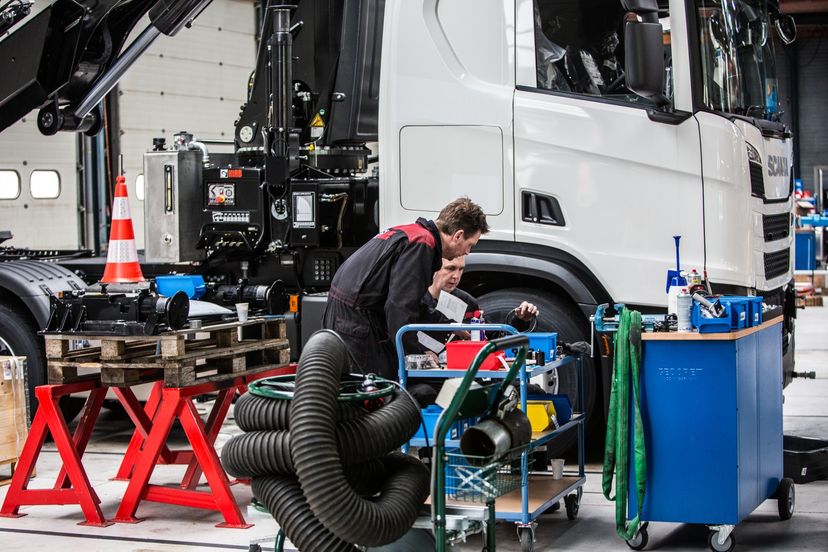

Smarter without a doubt

Hiab FrameWorks saves you a great deal of effort, but it also saves you headaches by eliminating risk. Installing a crane in one quarter of the time is a valuable proposition. And so is the opportunity to spend less time on sourcing and quality control.

But Hiab FrameWorks is smart in other ways too. All critical calculations are incorporated into the Hiab FrameWorks system, which leaves all the worry to us.

Faster without a doubt

Hiab FrameWorks is a modular system that minimises design work and cuts installation time by 75%.

Supplied ready-to-install for a specific truck and crane, a Hiab FrameWorks solution eliminates days of calculation and design hassle, as well as weeks of installation labour. The subframe is bolted on using the included attachment kit, with no welding or grinding involved. Nor is any lateral plating needed on the Truck chassis.

Ready without a doubt

Hiab FrameWorks is a full package that makes both delivery and future service a simple matter.

A Hiab FrameWorks solution is a complete solution that leaves nothing to chance. As well as the subframe, attachment kit and detailed mounting instructions, you get the oil tank and other key accessories along with the crane itself. That saves you sourcing elsewhere – and means easy access to Hiab spare parts and service down the road.

Book a meeting to find out more about FrameWorks

Speak to your nearest Hiab sales representative or dealer for more information

FIND A DEALER2. Bodyworks loader bodies

Benefits

Lightweight

Hiab BodyWorks are significantly lighter than any other loader body currently available. This means you can carry the same payload more economically, a higher payload at no extra cost, or any combination of the two. It’s a win for your bottom line, and a win for the environment, too.

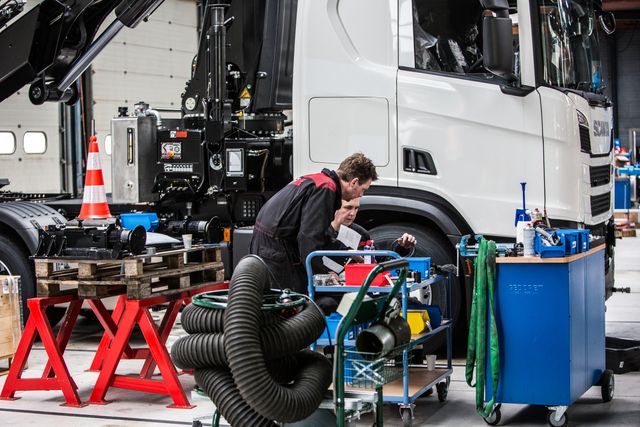

Easy to install

Our pre-manufactured modules make installation a breeze – around two weeks compared with up to eight weeks for a traditional loader body. This cuts 75% off the waiting time for a truck to be delivered and ready for use.

Easy to maintain

Our modular concept is designed for mechanical simplicity. The bolted construction is 100% weld-free, so parts are easy to remove and replace. That means big savings for you when it comes to maintenance time and labour costs.

Long-lasting

Corrosion is a killer for loader bodies. To ensure a long service life, Hiab BodyWorks are treated with our unique nDurance anti-corrosion coating. nDurance is Hiab’s advanced nanotechnology paint process, and it provides the industry’s toughest protection in all weathers.

Build your BodyWorks

Get the precise customized design you’ve always wanted at a price you can afford. Start with one of our three standard BodyWorks models: Basic, Basic+ and High-end. Then select from a range of interchangeable modules, options and accessories to get the perfect body for your loading needs and local requirements.

1. Choose a model

Three standard BodyWorks models: Basic, Basic+ and High-end. Read more below.

2. Choose modules, options and accessories

- Type of floor

- Stanchion rows

- Toolboxes

- Light carriers

- Accessories

- Rear extensions

3. Discuss options with a dealer or our sales representative

Dealers and our sales representatives can help you find the best solution for your equipment.

BodyWorks models

BODYWORKS BASICS

- Headboard module

- Wheel arch module

- Rear section

- Working lights

- Simple flooring option (wood)

- Standard toolboxes

BODYWORKS BASIC+

is the same as our Basic model, plus:

- Standard flooring, wood combined with steel above the rear axles

- Multiple toolboxes

- Additional lashing points

- Side rave continues to the cabin

- Stainless steel plating

BODYWORKS HIGH-END

is as Basic+, with additional pocket storage, and options including:

- Toolbox on top of headboard with working lights, supports for a spreader and ball coupling for a trailer.

- Wide load signs

- Stainless steel plating in front of fuel tank

- Step or toolbox between rear axles

Book a meeting to find out more about FrameWorks

Speak to your nearest Hiab sales representative or dealer for more information

FIND A DEALER

3. Mounting accessories and front stabilizers

Find a dealer to customize your FrameWorks subframe with accessories and stabilizers.

Our options include:

- Different oil tank solutions

- HIAB auxiliary stabilisers

- Variable pump

- Tank supports and other bracketry

Ready to find out more?

HiPerform

ProCare

HiConnect

©2025 Hiab Corporation